The world is constantly changing, and businesses have to adapt to survive. So what is Industry 4.0 – which seems to linger on everybody’s mind?

Over the last years, we’ve been experiencing a shift called the Fourth Industrial Revolution, with millions of businesses soon to adapt to this new paradigm shift.

As you’ll see, it’s a whole new way of thinking about manufacturing and operations, and it’s built on smart technology, connectivity, and data-driven decisions. It promises to transform the way we make things and run our businesses, with implications for every industry imaginable!

So keep reading! In this article, we’ll answer the question of what is Industry 4.0 by presenting its key technologies – and explain how it can help your business grow.

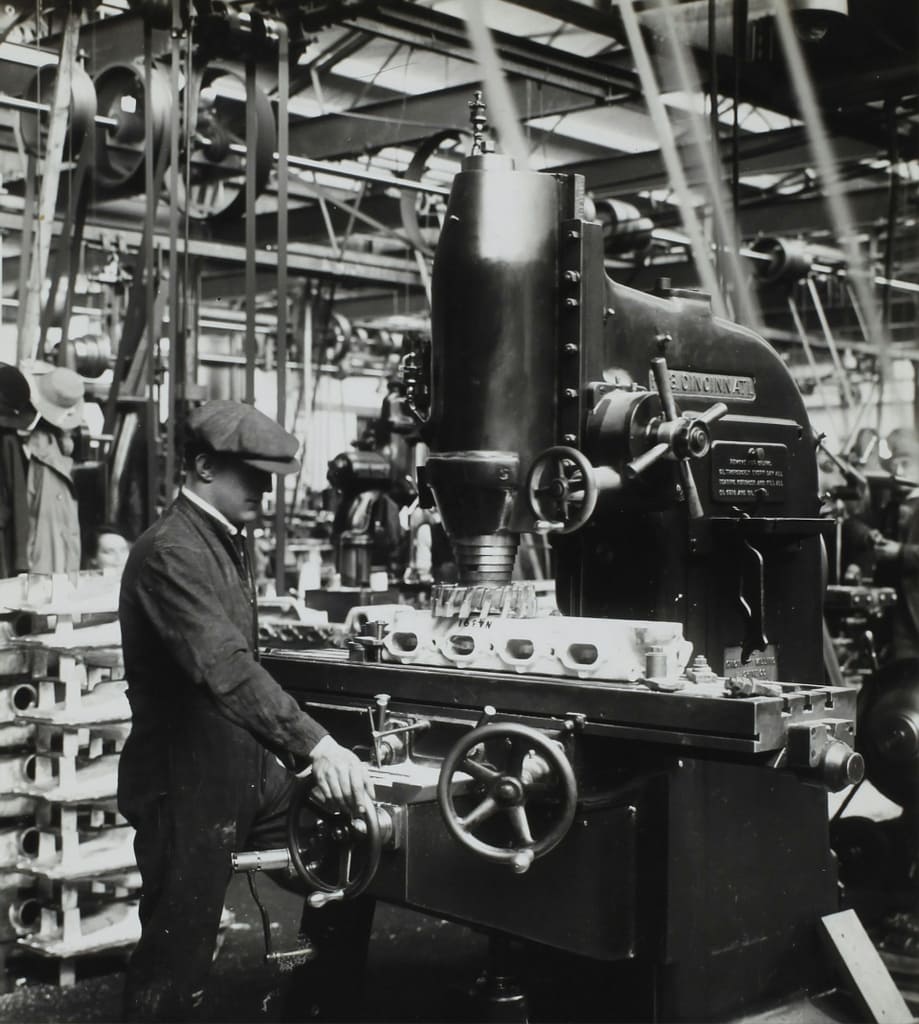

A quick trip through industrial history

Before we talk about this massive paradigm shift, let’s take a brief look at how things have evolved:

- The First Industrial Revolution: the whole thing started in the late 1700s with the invention of machines powered by water and steam. They made it possible to mass-produce goods in factories, a huge shift from the handmade crafts of the past;

- The Second Industrial Revolution: in the late 1800s, things ramped up even further with the arrival of electricity, the assembly line, and new methods of mass production. It became easier than ever to produce goods on a grand scale;

- The Third Industrial Revolution: the late 20th century brought the rise of computers and automation, using automated processes for factories. This led to greater efficiency, with many processes requiring very little manpower.

What is industry 4.0? Understanding the Fourth Industrial Revolution

The Fourth Industrial Revolution, or Industry 4.0, builds upon everything that came before, but it’s fundamentally about merging the physical and digital worlds.

Connectivity between hardware and software is one of its core principles, with machines constantly talking to each other and sharing data in real-time. It’s like creating a nervous system for your entire operation, allowing different parts to communicate and coordinate seamlessly.

Another key aspect is automation, but not just the kind we saw in the Third Industrial Revolution. Industry 4.0 is all about smart automation, using advanced technologies to handle complex tasks that previously required human intervention. Think of robots that can learn, adapt, and even make decisions on their own, a massive step-up from pre-programmed machines.

This interconnectedness facilitates seamless data exchange, creating a flow of information between every element of the system. This constant stream of data provides a detailed, real-time view of operations.

With all this data flowing, companies get real-time insights. Instead of relying on historical reports and guesswork, businesses can access up-to-the-minute information to make informed decisions.

Finally, Industry 4.0 emphasizes modularity and customization. The old model of rigid, mass production is giving way to more flexible and adaptable systems. Factories are becoming more modular, allowing for easier reconfiguration and customization to meet specific customer demands or rapidly changing market conditions.

The key technologies driving Industry 4.0

Several technologies are making Industry 4.0 a reality, such as:

- Internet of Things (IoT): at its core, IoT is a network of physical devices – “things” – embedded with sensors, software, and other technologies that enable them to connect and exchange data with other devices and systems over the internet or other communication networks. In essence, it makes everyday objects and industrial machinery “smart” and interconnected;

- Cloud computing: the cloud is a giant digital warehouse for all that data. It allows companies to store, process, and analyze huge amounts of information quickly and efficiently;

- Big Data analytics: using software to understand the data and identify trends. It can enhance productivity by making sure resources go exactly where they are needed the most;

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML can analyze data patterns, make predictions, and automate tasks. A popular use of these technologies includes the emergence of AI twins, which is a simulation of a digital entity that acts exactly like a real-life individual or object. If you can build a simulated version of your machinery, for example, the AI can tell you when maintenance will be needed, so it’s almost as if you have a factory that takes care of itself;

- Cyber-Physical Systems (CPS): CPS are the machines that combine computing, networking, and physical processes into one machine. You can control the machine itself thanks to the machine! All operations need to be safe from potential cyberattacks, so that the wrong hands don’t affect CPS operations;

- Additive manufacturing (3D printing): printing materials in 3D is a huge game changer to quickly make prototypes or even make products that were previously impossible;

- Augmented Reality (AR) and Virtual Reality (VR): training people on how to use and maintain equipment. These can make it easier for people to train and enhance their skills remotely;

- Autonomous robots: instead of being controlled by humans at all times, robots can make decisions and move freely. They can handle repetitive tasks and will soon be able to do inspections on their own.

Benefits and challenges of implementing Industry 4.0

Industry 4.0 presents businesses with a bright picture of tomorrow – a future filled with possibilities that could really change how things are done. This paradigm shift is about to transform how millions of companies operate, creating a smarter, more connected, and incredibly efficient system.

For example, imagine factories that can practically run themselves, spewing out products with amazing quality and responding to customer demands faster than ever before. With everything interconnected, you can expect higher productivity, streamlined operations, and lower costs across the board.

Companies that can successfully make this leap stand to gain a real advantage in the global market, discovering all-new ways to make money and provide unique value.

That said, this new paradigm also comes with big challenges to overcome. One of the biggest hurdles is simply the money it takes to get started. Implementing new technology is almost always expensive, which could scare some companies away from jumping on board.

Additionally, there’s the question of talent, or lack thereof. You don’t just buy the tech and plug it in, there needs to be someone capable of managing these complex systems. If your people aren’t prepared or they don’t have the proper training, you won’t be able to enjoy the full benefits.

Data security is also a major concern, more so knowing how data breaches can damage your company’s reputation and result in massive losses. The more things connect, the higher the risk of security breaches and cyberattacks.

Finally, getting new technologies to play nice with old systems can be a nightmare, creating headaches and slowing down progress. Well, have you ever wondered why legacy systems are still a thing in IT?

Now you know what Industry 4.0 is all about!

Even though getting there isn’t always easy, you can’t ignore the incredible opportunities Industry 4.0 brings to the table. Adapting to this new landscape lets businesses boost productivity, work more efficiently, and come up with truly innovative ideas.

It’s time to look beyond just automating what you already have and create a business that’s smarter, faster, and ready for anything.

Are you ready to start building your Industry 4.0 future? Datanet IoT is your dedicated partner with custom, high-quality solutions for tracking and environmental monitoring. What if you could maintain the perfect temperature for your raw materials to preserve quality?

What about monitoring the exact location of your expensive research equipment, even when it is thousands of miles from land? How about monitoring the water quality for your fish farm, or anything in between? Contact us today and let’s make your dreams a reality!