The global shipping industry moves over 90% of the world’s goods, yet until recently, tracking these containers was akin to navigating a labyrinth blindfolded. Enter sea container tracking – a technological leap powered by the Internet of Things (IoT) that transforms opaque logistics into a transparent, data-driven process.

Recent studies indicate that IoT in logistics is a $35 million industry with a 13.2% growth rate predicted for the next ten years. This article explores how IoT sensors, real-time analytics, and smart containers are reshaping maritime logistics, offering unprecedented visibility, security, and efficiency.

Discover how these innovations work, why they matter, and how businesses like yours can leverage them to stay competitive in an increasingly complex global market.

The evolution of sea container tracking

For decades, tracking a shipping container’s journey relied on fragmented port updates and manual logs. A container could vanish for weeks, only to reappear with damaged goods or delayed timelines.

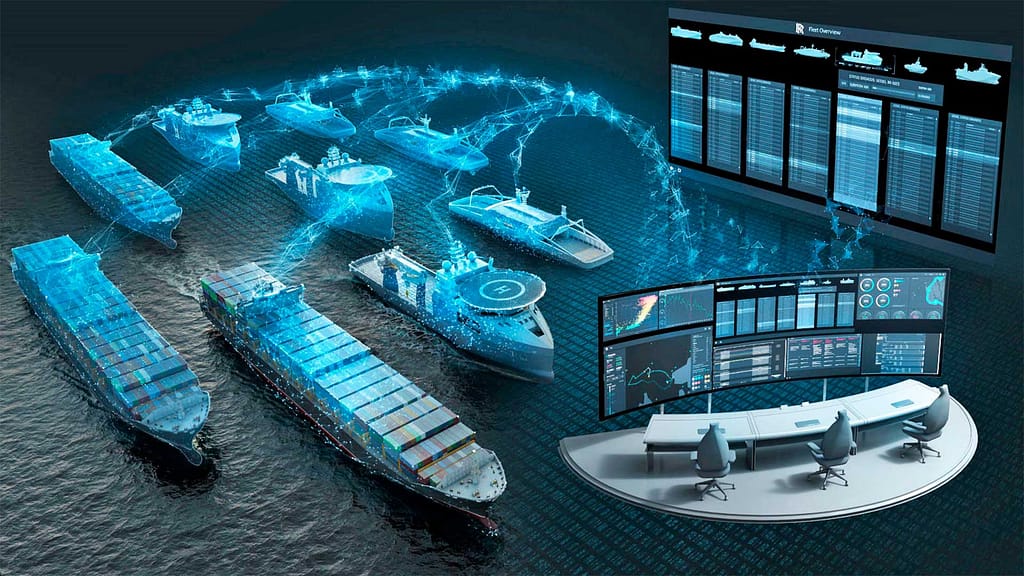

Today, IoT-enabled sea container tracking systems equip containers with sensors that monitor location, temperature, humidity, shocks, and even unauthorized access in real time. These devices transmit data via satellite or cellular networks to centralized platforms, allowing stakeholders to monitor shipments across oceans, railways, and roads seamlessly.

Take, for example, a pharmaceutical company shipping vaccines. Without IoT, temperature fluctuations during transit might go unnoticed until spoilage occurs. With smart containers, sensors trigger alerts the moment conditions deviate, enabling immediate corrective action. This shift from reactive to proactive logistics isn’t just innovative – it’s transformative.

3 core technologies powering modern sea container tracking

At the heart of sea container tracking are three pillars: IoT sensors, connectivity networks, and data analytics platforms.

- IoT Sensors: Compact devices attached to containers collect data on environmental conditions (temperature, humidity), physical events (shocks, tilts), and security breaches (door openings).

- Connectivity Solutions: Transmitting data from the middle of the ocean requires robust networks. Dual-mode systems switch between satellite and cellular networks to maintain uninterrupted coverage.

- Analytics and AI: Raw data becomes actionable insights through machine learning. Predictive algorithms analyze historical trends to forecast delays, optimize routes, and even preempt maintenance issues.

Read also: How a moisture tracker can revolutionize your industry

Benefits for businesses and the environment

The adoption of IoT-driven sea container tracking isn’t just a technical upgrade – it’s a strategic advantage.

- Enhanced Visibility: Companies gain end-to-end transparency, from factory floors to final destinations. Integrated platforms merge IoT and AIS vessel tracking, allowing users to monitor cargo across land and sea on a single dashboard.

- Risk Mitigation: Theft and damage account for billions in annual losses. Sensors detecting unauthorized door access or sudden impacts enable swift interventions. For high-value goods, this means fewer insurance claims and higher customer trust.

- Sustainability Gains: Optimized routing reduces fuel consumption and emissions. IoT tracking deployment cuts idle times and improves container utilization, aligning with global decarbonization goals.

- Regulatory Compliance: Industries like pharmaceuticals and food require strict condition monitoring. IoT systems automatically log temperature and humidity data, simplifying compliance audits.

Overcoming challenges: costs, security, and integration

While the benefits of IoT-driven sea container tracking are clear, implementation is not without its challenges.

Businesses must navigate financial barriers, cybersecurity risks, and the complexities of integrating new technologies with legacy systems. Addressing these hurdles requires strategic planning, innovative solutions, and partnerships with trusted experts.

Starting with costs. The upfront investment in IoT infrastructure can be daunting. High-quality sensors, satellite or cellular connectivity modules, and cloud-based analytics platforms often represent significant capital expenditure. Furthermore, software subscriptions for real-time dashboards and predictive analytics tools further inflate initial costs.

However, forward-thinking companies are mitigating these expenses through creative financing models. Some opt for “sensor-as-a-service” subscriptions, where providers lease hardware for a monthly fee, reducing upfront burdens.

Others leverage ROI-driven pilots, deploying trackers on high-risk or high-value shipments first to quantify savings from reduced theft, spoilage, or delays.

Over time, optimized routing and predictive maintenance can cut fuel costs by up to 15% and extend container lifespans by 20%, transforming IoT from a cost center to a profit driver.

Cybersecurity is another big concern. As containers become data hubs, they also become targets, with hackers exploiting vulnerabilities in IoT devices to hijack cargo data or disrupt operations.

To combat such threats, the industry is adopting layered security frameworks. End-to-end encryption ensures data remains unreadable even if intercepted. Blockchain technology is gaining traction for creating immutable audit trails.

Meanwhile, regular firmware updates and zero-trust architectures – where every device and user must continuously validate access – are becoming best practices. Compliance with regulations like ISO/IEC 27001 and GDPR further compels companies to adopt robust cybersecurity measures, turning IoT systems into fortresses rather than liabilities.

Ultimately, overcoming these challenges demands collaboration. Industry alliances are fostering standards for interoperability, while governments are subsidizing IoT adoption through grants, such as the EU’s Horizon 2020 program.

Businesses that proactively engage with cybersecurity firms, IoT specialists, and even competitors to share best practices will thrive in this new era.

Read also: CSRD timeline: a comprehensive guide for all businesses

The future of autonomous supply chains and beyond

The next frontier for sea container tracking lies in autonomy and hyper-connectivity. 5G networks will enable faster data transmission, while AI-driven predictive analytics will refine ETAs to near-perfect accuracy.

Moreover, sustainability will drive innovation. As regulatory pressures mount, IoT data will help companies minimize empty container trips and optimize energy use in reefer units. The result? A greener, more resilient supply chain.

The era of guessing games in logistics is over. Sea container tracking powered by IoT isn’t just a tool – it’s a paradigm shift, offering businesses the clarity and control needed to thrive in a volatile market. From preventing spoilage to slashing carbon footprints, the applications are as vast as the oceans these containers traverse.

For companies ready to embark on this transformation, the journey begins with a single step. Explore how IoT can redefine your logistics strategy, and consider partnering with experts who specialize in tailored solutions.

And we here at Datanet IoT are ready to take that first step with you. Contact us today to chart a new course and unlock the full potential of your supply chain.