In today’s fast-paced industrial landscape, efficiency and sustainability are paramount. As factories strive to streamline their operations and reduce their environmental footprint, advanced technologies and factory asset tracking are playing an increasingly crucial role.

This increasing concern with the environmental footprint has led the European Union to create the Corporate Sustainability Reporting Directive (CSRD) in 2024 as a means to measure the impact of corporate activities on the environment and society.

In this context, factory asset tracking is no longer just a tool to implement efficient production, but a strategic weapon in the fight for environmental, social, and governance transparency – and a powerful ally to future reporting of CSRD metrics as well.

So let’s discuss some details aspects of the CSRD and how factory asset tracking enters the equation!

What is factory asset tracking?

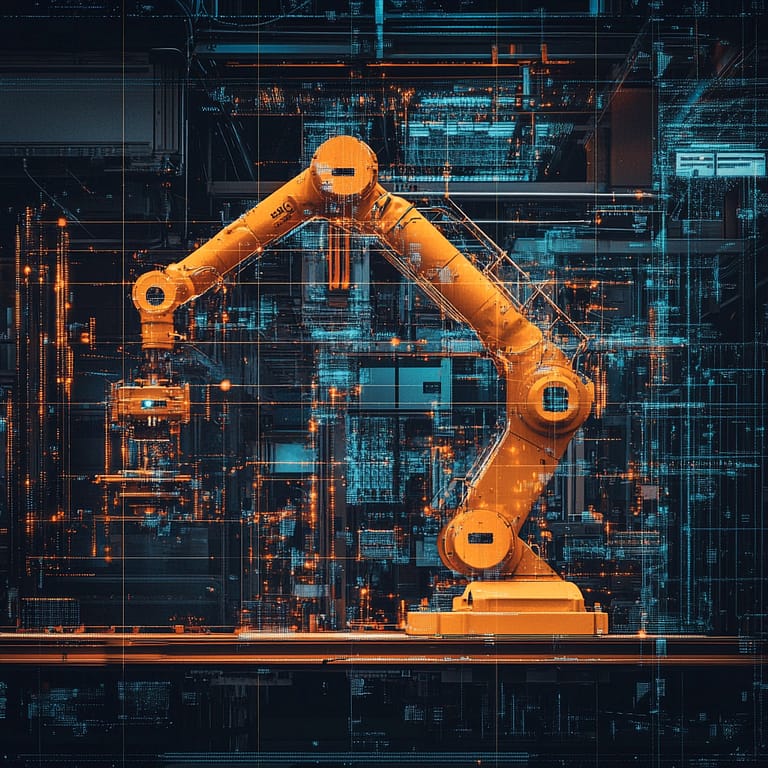

Factory asset tracking refers to the process of monitoring and managing physical assets within a manufacturing facility. These assets can include machinery, equipment, tools, vehicles, and other resources essential for the production process. Traditionally, asset tracking in manufacturing facilities relied heavily on manual processes, spreadsheets, and outdated systems.

However, this approach often led to inaccuracies, inefficiencies, and increased chances of errors. With sprawling factory floors housing a multitude of equipment, tools, and machinery, keeping track of every asset’s location, condition, and maintenance schedule became a daunting task.

But then came factory asset tracking solutions powered by cutting-edge technologies such as RFID (Radio-Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence).

These solutions provide real-time visibility into the location and status of assets throughout the manufacturing process – and have completely changed the game when it comes to productivity, maintenance, and control of assets throughout the production cycle.

RFID (Radio-Frequency Identification) tags are at the heart of this tracking system. Each asset is equipped with a unique RFID tag containing electronic data that can be wirelessly transmitted to RFID readers positioned strategically throughout the factory floor.

As assets move through various stages of production, RFID readers automatically capture and record their whereabouts, providing accurate and up-to-date information on their location and movement.

IoT (Internet of Things) sensors also play a crucial role in factory asset tracking. These sensors are embedded in machinery, equipment, and other assets, collecting a wealth of data on performance metrics, usage patterns, environmental conditions, and more.

And finally, AI (Artificial Intelligence) algorithms are increasingly being integrated into factory asset-tracking solutions to analyze vast amounts of data collected from RFID tags and IoT sensors.

These AI-powered analytics tools can identify patterns, trends, and correlations in the data, enabling manufacturers to gain deeper insights into their operations and make more informed decisions.

Factory asset tracking and CSRD reporting

But why is factory asset tracking so important to CSRD compliance?

The CSRD compels companies to gather and analyze data to support their sustainability claims – this incentivizes investment in robust asset-tracking systems. There are three aspects that companies should focus on:

- Real-time data collection

Focusing on continuous and immediate monitoring of resource consumption and potential sustainability issues is pivotal. - Advanced analytics

It is also important to identify trends and correlations between asset use and environmental impact to always move towards a more efficient and sustainable practice. - A systematic view of the operation

A holistic view of sustainability performance across the entire operation is also important. This holds true even when working with third-party companies. By CSRD standards, any emissions they produce when providing services for your company count as if they were your own.

Investing in advanced factory asset tracking for CSRD compliance isn’t just about ticking boxes. It’s an opportunity to reduce costs by improving resource efficiency, which then translates to lower energy and material expenses.

Besides, by tracking the energy consumption of equipment, companies can identify areas for optimization, reducing their overall environmental footprint and monitoring their lifecycle, facilitating responsible material sourcing, reuse, and recycling at the end of life.

Tracking emissions is also another big advantage. Data on fuel consumption of vehicles and equipment used on-site can contribute to accurate greenhouse gas (GHG) reporting and help ensure proper maintenance and adherence to service schedules, contributing to a safer work environment.

You may also like: The difference between EMS and GPS monitoring

Being prepared for this future

The CSRD may present a challenge at first, but it is also an opportunity for factories. By leveraging the power of asset tracking, companies can not only comply with regulations but also embark on a path toward a more sustainable and productive future.

With a data-driven approach to resource management and social responsibility, factories can transform asset tracking from a logistical tool to an ESG powerhouse.

That’s why factory asset tracking is no longer just a luxury, but a necessity for manufacturers striving to stay competitive in today’s fast-paced marketplace. By harnessing the power of RFID, IoT, and AI, manufacturers can unlock new levels of efficiency, productivity, and operational visibility.

As technology continues to advance, the possibilities for optimizing factory operations are virtually limitless, paving the way for a future where every asset is tracked, managed, and optimized with precision.

And if you’re looking to be a part of this revolution, we here at Datanet IoT are ready to help you with our asset-tracking solutions!

The Thingfox T2 Airfreight, for example, is the perfect tracker for the third-party compliance that we mentioned previously. Measuring the emissions of machinery your company does not necessarily own can pose quite a challenge – but not with the Thingfox T2 Airfreight. When it comes to logistics and transportation, you can simply plug it into a truck, and it’s ready to report the gas and CO2 consumption for every delivery into your factory or out to the client.

So get in contact with us to learn more about our products and schedule a presentation. Be ready for the future of CSRD compliance with the most efficient factory asset tracking in the market.